Dispatch 45kw Ammonia Gas Low Vacuum Nitriding Furnace for Extrusion Mould

Delivery one set of 45kw nitriding furnace to India.

Features of nitriding furnace:

1,low vacuum:-0.08Mpa

2,gas type:ammonia gas,ammonia gas nitriding furnace

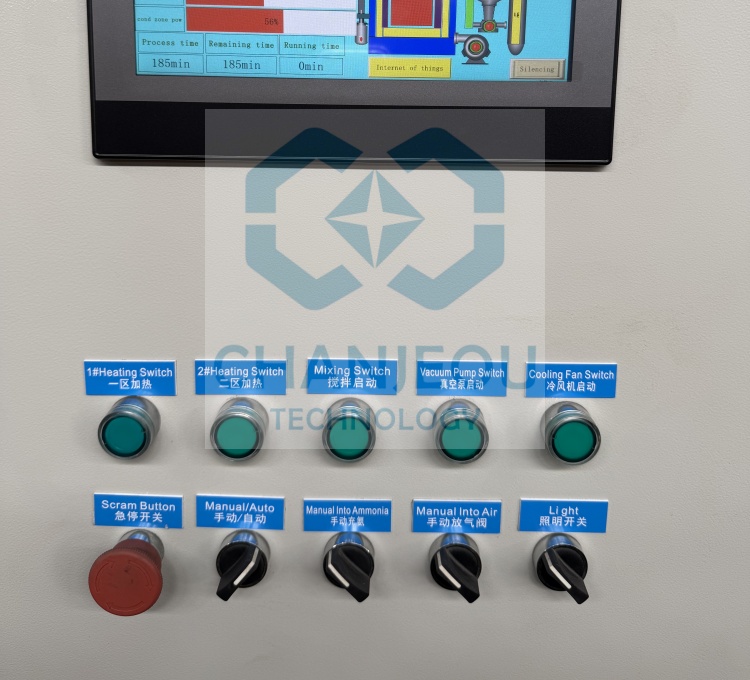

3,full automatic : manual and automatic operation

4,heating type:heating wire

5,lining material:Stainless

6,door open:button open/close

7,door thickness:30cm

8,thermal insulation material:rock wool, no break.

Top brand touch screen display ,with operation button

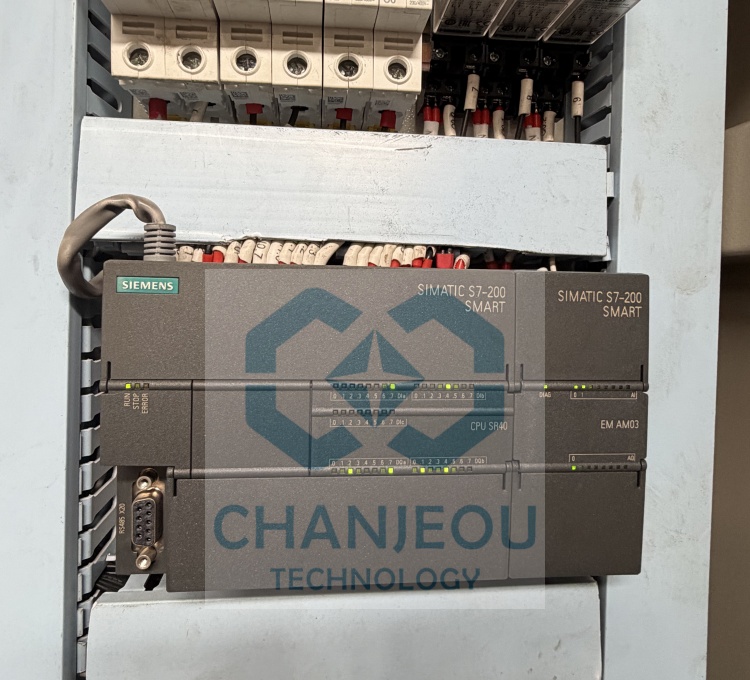

Siemens S7-200 series PLC,also with ammonia gas flowmeter ,show ammonia gas flow ,and total consumption.

Stainless basket for holding the extrusion mould

button operation for door open and close, after close, interlock of low vacuum nitriding furnace door

gas nitriding furnace main body and control cabinet

Gas nitriding furnace main body

The key parameters for good effect of gas nitriding furnace:

1,Temperature of low vacuum nitriding furnace: Nitriding temperature is one of the core parameters.

Impact for ammonia gas nitriding furnace : Higher temperatures accelerate the diffusion rate of nitrogen atoms and result in a thicker nitrided layer. However, excessively high temperatures can cause grain growth, reducing the workpiece's toughness and increasing deformation. Conversely, excessively low temperatures slow down the reaction, leading to inefficiency.

2,Time for ammonia gas nitriding furnace: The insulation time determines the duration of nitrogen atom diffusion.

Effect: The longer the time, the thicker the nitrided layer typically becomes, but the increase in thickness is proportional to the square root of time, meaning that as the treatment duration extends, the efficiency of thickening gradually decreases.

3,Nitrogen potential/ammonia decomposition rate of low vacuum nitriding furnace: This is the key to controlling the quality of the nitrided layer.

Impact of ammonia gas nitriding furnace: Excessively high nitrogen potential may lead to the formation of a loose compound layer (white layer) on the surface, making the nitrided layer brittle; conversely, insufficient nitrogen potential results in slow nitriding, inadequate surface hardness, and insufficient layer depth.

Too low (<15%): Insufficient nitrogen supply results in low hardness.

Excessive (>40%): An excess of hydrogen can hinder the penetration of nitrogen atoms, leading to a reduction in hardness and potentially impairing corrosion resistance due to the precipitation of chromium nitrides.

Chanjeou technology 45kw nitriding furnace is popular used in India,mature program of nitriding process for extrusion die, during process, any question,contact us, online guide to get perfect nitriding furnace effect.

45kw nitriding furnace parameters:

| Capacity | 45kw |

| Rated temperature | 650 degree |

| Basket size | Dia.550*1000mm |

| Temperature uniform | ±5℃ |

| Vaccum limit | -0.08Mpa |

| Heat up time | less than 80min |

| Loading weight | 500kgs |

Contact us for 45kw nitriding furnace:

| email:melody@chanjeou.com |

| whats app:+86 13450531604 |