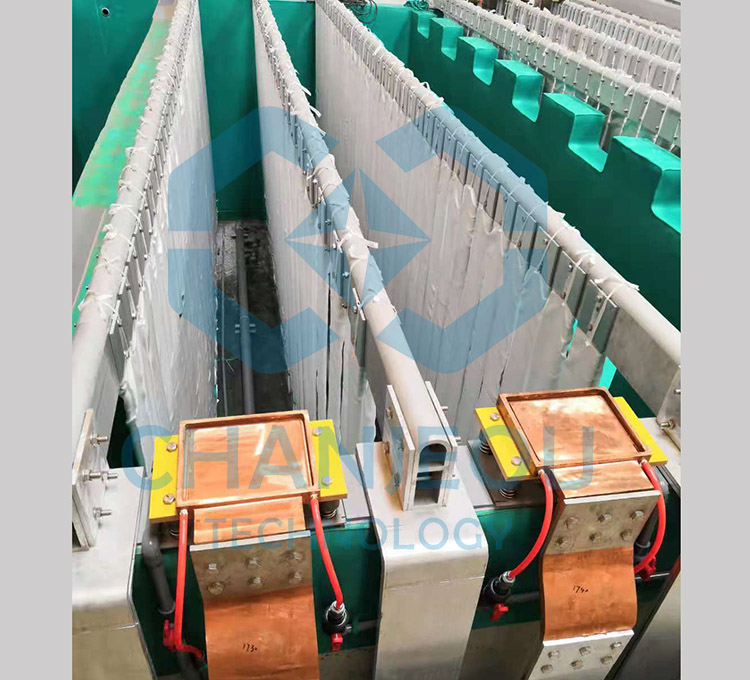

Durable Hot Sell Durable High Quality Automatic Aluminium Anodizing Plating Line

Brand CHANJEOU

Product origin CHINA

Main technical features: main transformer composed of five cores made of orientation silicon iron, without balance reactor

energy-saving structure.

1. High reliability and high efficiency transformation, low temperature rising;

2. Output voltage 0-24V stepless voltage regulation (input voltage380V±5%).

3. Negative double-pulse trigger is used for thyristor, safe and reliable;

4. Precision time counting (0-99h) and soft start-up (0-180s) are set;

High Quality Automatic Aluminium profile Anodizing Plating Line

Including:

1 set degreasing tanks,

2 set alkaline etching tank,

1 set neutralizing tank,

4 set anodic oxidation tanks,1 for preparing

2 set colouring tanks,1sealing tanks,

13 set rinsing tanks,

2 set oxidation overflow tank,

1 set hot rinse tank.

Process parameters: The sulfuric acid concentration is typically 150-200g/L, with temperature controlled at 20±2℃, current density ranging from 100-200A/m² (or 1-3A/dm²), and a treatment time of approximately 30 minutes to 2 hours.

Process: Aluminum, serving as the anode, forms a porous alumina film on its surface after being electrified.

we can according customer require set special line.

Customization direction

Process parameter customization: Adjust oxidation time, temperature, solution concentration, etc., to accommodate different materials (such as aluminum, magnesium alloys) or thickness requirements.

Equipment configuration customization: Design the line length and automation level (such as robotic loading and unloading) according to production capacity requirements, or integrate specific post-processing (such as sealing and dyeing).

Function and certification customization: Enhance corrosion resistance and adhesion according to industry requirements (such as automotive and medical), and support obtaining relevant certifications (such as RoHS and ISO).

Appearance and effect customization: Provides options for different colors (such as black, colored) or gloss levels (matte, glossy) to meet decorative needs.

Aluminum Workpiece

↓

[Chemical Degreasing] → Rinse // Remove oils and contaminants

↓

[Alkaline Etching] → Rinse // Create uniform matte surface (NaOH, 50–80 g/L, 50–70°C)

↓

[Neutralization] → Rinse // Remove residual alkali (HNO₃ or mixed acid)

↓

[Anodic Oxidation] → Rinse // Form porous Al₂O₃ layer (H₂SO₄, 150–200 g/L, 20±2°C, 1–3 A/dm², 30 min–2 h)

↓

[Electrolytic Coloring (Optional)] → Rinse // Deposit metal salts for color (e.g., black, bronze)

↓

[Sealing] → Rinse // Close pores via hot water or nickel acetate (improves corrosion resistance)

↓

[Post-Treatment (e.g., Deashing)] → Rinse // Ensure surface cleanliness

↓

[Drying] (60–80°C) → [Inspection] → [Packaging]

After sale-service

Provide the best factory building support and machine design technical support,

and after-sale support machine usage guide instruction, and field video guide.

If necessary we can send professional technicians there.