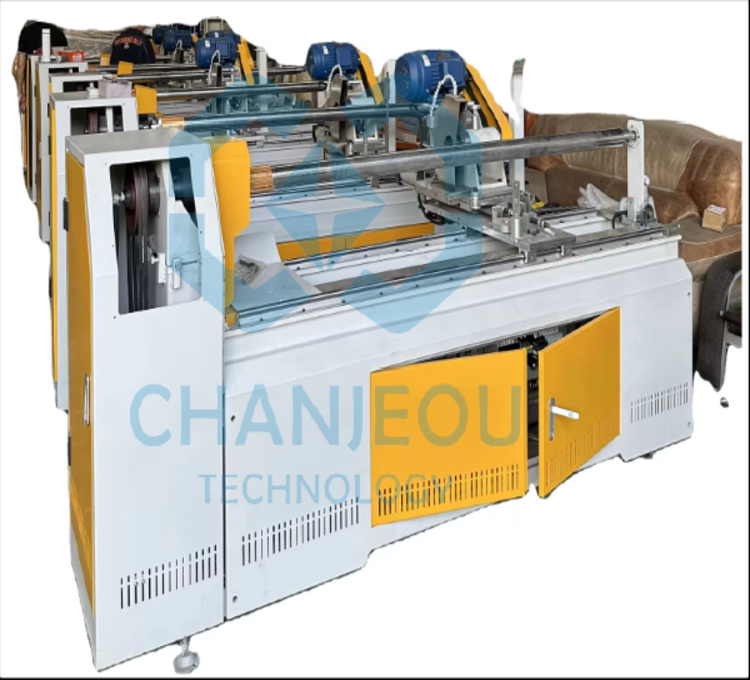

Manual and automatic film cutting machine

Brand Chanjeoy

Product origin Guangdong

Delivery time 20 days

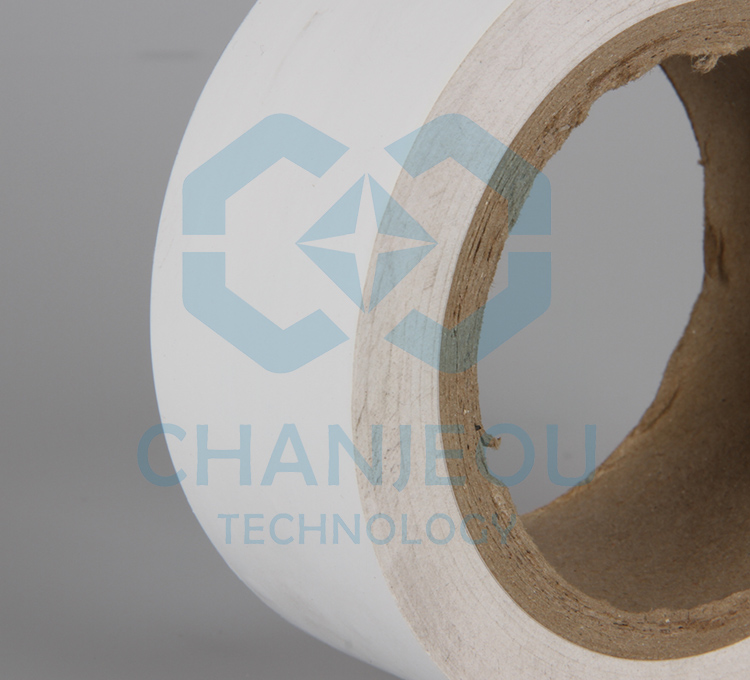

The film cutting machine is used to slit roll material,such as roll folding paper and plastic films, with advantage of simple mechanical structure ,convenient and agile in operation and high-speed in split-cutting and so on.

The film cutting machine is a professional printing device, mainly used for slitting various film materials.

Supply customized film cutting machines in two types: manual plastic films slitting machines and automatic film cutting machines.

manual plastic films slitting machine

automatic film cutting machine

The main features and advantages of are as follows:

1. High-precision cutting:

The film slitting machine adopts advanced cutting technology, featuring high precision and stability. It can achieve precise slitting and control, ensuring product quality and yield.

2. High-efficiency production:

The automatic film cutting machine has many outstanding features. Firstly, in terms of performance, the automatic film cutting machine adopts an advanced transmission system and control system, which can achieve high-speed and stable slitting operations, significantly enhancing production efficiency. Compared with traditional paper roll slitting machine, the automatic film cutting machine can complete more slitting tasks within a unit of time, improving production efficiency and economic benefits.

3. Multi-functional application:

The plastic films slitting machine can be used for slitting various materials, such as composite paper rolls and plastic films, and is widely applied in the printing industry.

4. Easy to operate and learn:

The plastic films slitting machine is equipped with a touch screen control system and intelligent processing programs, making it easy to operate and learn. No professional skills or senior operators are required to operate and maintain the equipment.

5. Energy conservation and environmental protection:

The paper roll slitting machine adopts a highly efficient energy consumption reduction design, which can achieve energy conservation and environmental protection, while reducing the waste of energy and materials, and is more in line with the concepts of low-carbon economy and sustainable development.

6. Strong stability:

Body of paper roll slitting machine structure is reasonably designed and high-quality components are selected, which can operate stably for a long time and reduce the frequency of shutdown maintenance.

Main technical parameters of plastic film slitting machine:

Power: | 380V,50Hz(Customized) |

| blade length: | 300mm |

total power: | 1.5kw |

max length of roll film: | 1600mm |

Overall dimension: | 2100*760*1110mm |

Maintenance and security of Pater Roll Slitting Machine:

1,Check daily

Before working,add enough lubricating oil on the sliding block and make sure the trailer flexible. Start the main motors, judge whether there have unusual noise. Please keep the machine clean and neat after work.

2,Check monthly and yearly

Check and add lubricating oil on the main axis and bearing of the cutter head monthly and yearly.

3, In case of injured, forbidden touching the blade,when it is rotating.