Deliver 45ks Nitriding Furnace Machine for Extrusion Mould to India

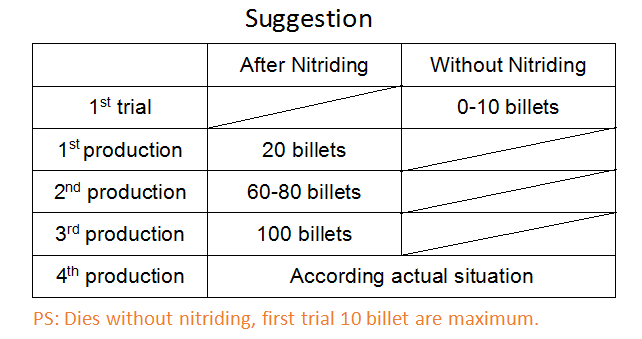

Nitriding furnace is popular used in aluminum profile extrusion line, use for increasing hardness of extrusion die after extrusion some time, the following is the list suggestion for nitriding process frequency:

Advantage of Chanjeou company Nitriding machine:

1,full automatic

2,Siemens PLC, Siemens touch screen

3,popular used in India

4,reliable service

5,reliable quality

6,good price of value

7,no need send engineer for installation, online guide to finish installation

Dispatch 45kw extrusion die nitriding furnace to India photo:

45kw nitriding machine loading photo

Extrusion die nitriding machine main parameters:

| Capacity | 30kw | 45kw | 60kw | 75kw | 90kw |

| Basket size | Dia.450*650mm | Dia.550*1000mm | Dia.650*1200mm | Dia.800*1200mm | Dia.800*1800mm |

| Loading weight | 200kgs | 500kgs | 800kgs | 1000kgs | 1800kgs |

| Limited vacuum | -0.08Mpa | -0.08Mpa | -0.08Mpa | -0.08Mpa | -0.08Mpa |

| Furnace temperature uniform | ±5℃ | ±5℃ | ±5℃ | ±5℃ | ±5℃ |

Extrusion die nitriding furnace for extrusion molds is heat treatment equipment specifically designed for surface treatment of aluminum extrusion molds. Its core function is to form a high hardness infiltration layer on the mold surface through nitriding technology to enhance wear resistance and service life.

Specialized process and temperature control for extrusion die nitriding furnace: The nitriding furnace for extrusion molds usually adopts gas soft nitriding process (such as nitrogen carbon co nitriding), with a processing temperature controlled in the low temperature range of 520-590 ° C to balance the hardness of the nitriding layer and the toughness of the substrate, avoiding mold deformation or cracking; Temperature uniformity needs to be strictly guaranteed, generally requiring a temperature difference of less than ± 5 ° C inside the furnace to ensure consistency in the thickness of the infiltration layer.

Structural design and furnace temperature uniformity for nitriding furnace: The equipment often adopts a well furnace structure, equipped with dual water-cooled furnace covers, zone heating elements, and composite furnace lining. The furnace temperature uniformity is improved through a multi zone temperature control system (upper and lower zones); Stainless steel material is commonly used for furnace tanks and integrated with PLC program control systems to achieve automated management of heating, insulation, and cooling processes.

Cooling efficiency and infiltration layer quality for extrusion die nitriding machine: In order to meet the repeated nitriding requirements of the mold, the equipment is often equipped with a dual cooling system that combines air cooling and water cooling. The cooling interlayer and bottom air cooling mechanism accelerate the cooling process, shorten the cooling time, and reduce thermal stress; The rotatable design of the furnace turntable or carrier helps to improve the uniformity of nitriding, reduce the contact area between the mold and the furnace body, and avoid local overheating.

Application adaptability and process flexibility for extrusion die nitriding furnace: The nitriding furnace needs to support multiple repetitions of nitriding to meet the requirement of a layer thickness of 0.15mm during the service life of the mold; The process parameters (such as temperature, time, ammonia decomposition rate) can be adjusted to adapt to different types of mold steel (such as hot work mold steel), and the ability to resist crack propagation can be improved by optimizing the microstructure of the infiltration layer (such as controlling brittle phases).

Energy saving and safety for nitriding machine: The new equipment adopts gas heating instead of traditional electric heating, which improves thermal efficiency by 30% -50%; Sealing structures (such as vacuum rubber seals) and furnace pressure detection devices can prevent atmosphere leakage, combined with safety interlock mechanisms to reduce operational risks

Chanjeou technology supply reliable extrusion die nitriding machine, freely contact us for nitriding machine:

Contact us for extrusion die nitriding machine:

email:melody@chanjeou.com whats app:+86 13450531604 |