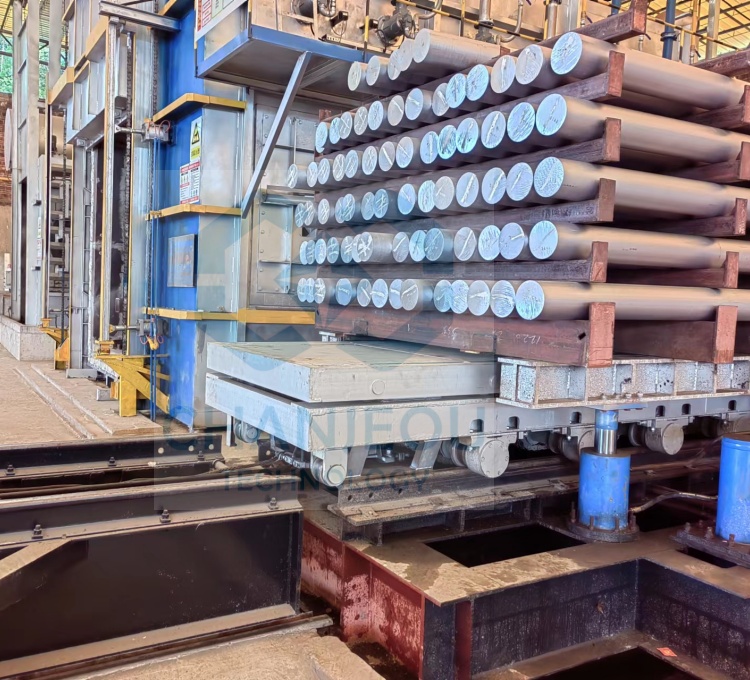

Aluminium Billet Homogenizing Oven

Aluminum Billet Homogenizing Oven Main Features:

1,energy saving ,recycle exhausted air temperature

2,different program for different series aluminum alloy

3,customized design

The homogenizing oven for aluminum profile melting and casting is mainly used to eliminate internal stress, chemical composition, and structural inhomogeneity of aluminum ingots, in order to improve their processing performance and the mechanical properties of the final product.

Main function of billet homogenizing oven:

The core function of the aluminum profile melting and casting aluminum billet homogenizing oven is to homogenize the cast aluminum rod (ingot), including:

Eliminating internal residual stress: Through a controlled heating process, the internal stress generated during the cooling process of the ingot is released to prevent deformation or cracking during subsequent processing (such as extrusion).

Homogenization of microstructure and composition: Eliminating grain size differences and chemical composition segregation (such as uneven distribution of elements such as magnesium and silicon) inside the ingot, making the alloy structure more consistent.

Enhance material performance: Improve the plasticity, strength, and toughness of aluminum materials, laying the foundation for subsequent extrusion or forging processes.

Working principle and process:

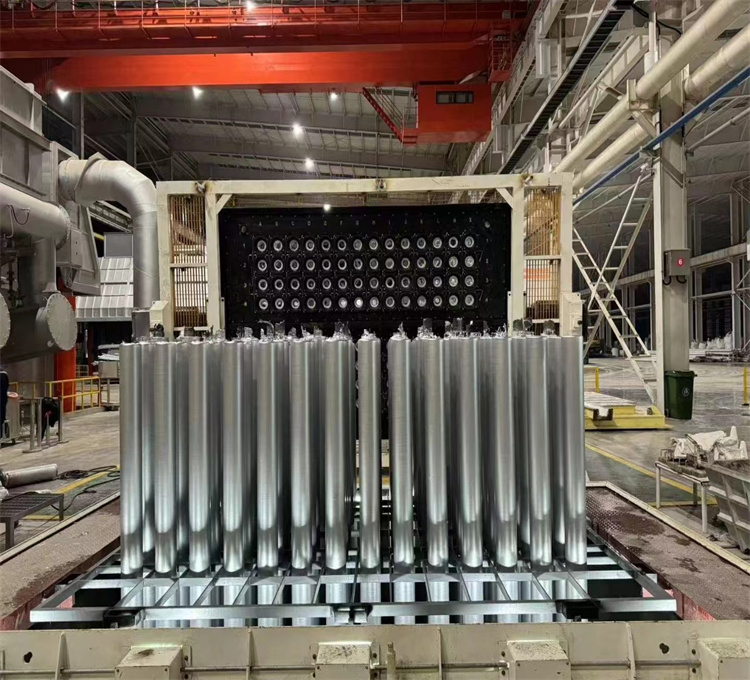

Aluminum billet homogenizing oven achieves homogenization treatment through precision temperature control system:

High temperature heating: Heat the aluminum ingot to a specific temperature (usually around 570 ° C) to allow atoms to diffuse fully and promote component homogenization.

Insulation stage: Maintain the temperature for a period of time to ensure that the internal organization is fully reorganized.

Cooling control: using air or water cooling systems for efficient cooling, fixing uniform structures, while saving energy and reducing consumption.

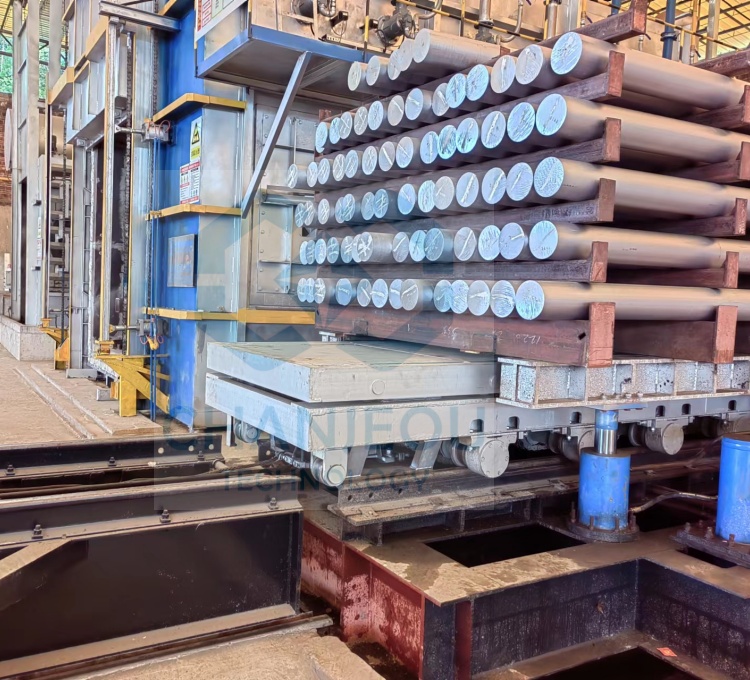

The direct benefits of homogenization treatment include:

Optimize processability: reduce extrusion resistance, allow for the production of thin-walled or complex cross-section profiles, improve extrusion speed and mold life.

Enhance product quality: avoid surface defects such as cracks or bubbles, improve the mechanical properties and oxidation resistance of aluminum profiles.

Cost effectiveness: Achieve efficient energy consumption ratio and reduce production costs through automated control systems (such as PLC)