Automatic aluminum profile packing wrapping machine and glue film bundle machine

Automatic aluminum profile packing wrapping machine and glue film bundle machine:

1,automatic packing wrapping machine

2,automatic glue film bundle machine

3,sevo control

4,PLC control, screen operation

Automatic aluminum profile packing wrapping machine and glue film bundle machine features:

1,PLC control,screen set parameters

2,Servo control

3,Supply customized design :

one set of glue film bundle or two sets of glue film bundle machine

wrapping speed are adjustable by VFD

wrapping size is customized,200*200mm,300mm*300mm,350mm*350mm etc.

4,wrapping tight or not tight are adjustable

5,wrapping film width are adjustable

Supply three kinds of aluminum packing machine:

| wrapping film packing machine |

| heat shrinking film bag packing machine |

| protective film taping machine |

Aluminum wrapping machine is widely used for long way transport, protect aluminum , avoid scratch very well.

Packing Wrapping Machine and Film Bundle Machine Operation features:

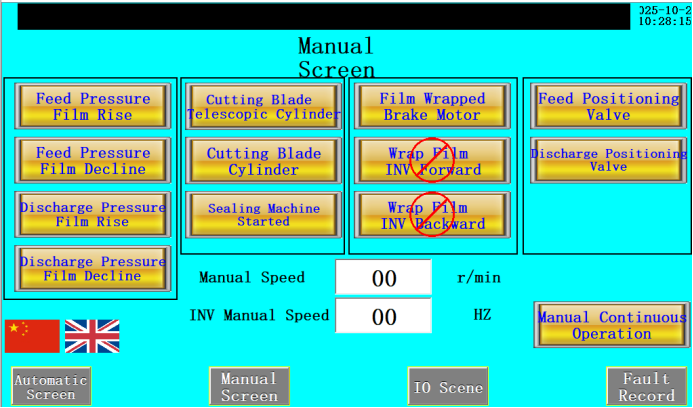

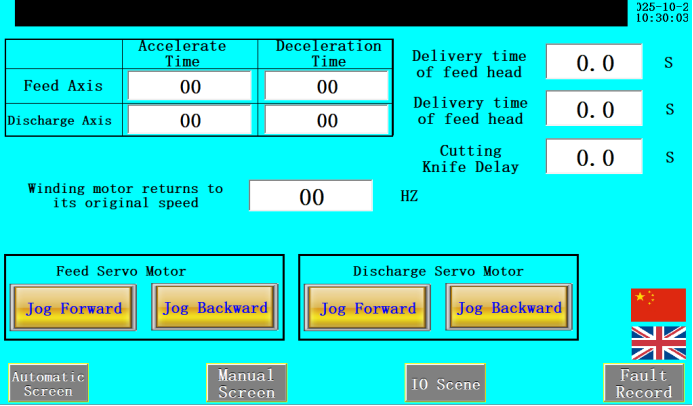

Packing Wrapping Machine Manual Screen: In manual mode, the solenoid valve and film-winding frequency converter can be tested for jogging.

Feed press film up/down: The press film cylinder at the feed position.

Feed-out film pressing cylinder rise/fall for packing wrapping machine: The film pressing cylinder at the feed-out position.

Cutting blade telescopic cylinder for packing machine: When the tail of the material is about to wrap around the tail film, it extends to pull the film into a strip shape, making it convenient for the cutting blade cylinder to cut. When it is necessary to replace the film cylinder, you can click on the touch screen in manual mode, or there is a cylinder expansion knob next to the emergency stop button to control the cutter expansion cylinder to extend, making it convenient to wrap the film head tightly after replacing the film cylinder.

Knife cylinder for packing wrapping machine: used to cut wrapping film.

Film wrapping brake motor for aluminum wrapping machine: The brake of the film wrapping motor needs to be opened before running it

Film winding motor forward/reverse: The film winding motor operates manually in both forward and reverse directions.

Glue film bundle machine startup: The material head and tail are packaged and wound to start the machine.

Feed positioning valve for packing machine: The function of clamping at the feeding point.

Discharge positioning valve for packing wrapping machine: The function of clamping at the discharge point.

Manual speed for packing machine: The speed at which the feed and discharge servos operate manually.

Manual speed of frequency converter for packing wrapping machine: the speed at which the film winding motor operates manually

Manual continuous operation for aluminum wrapping machine: In manual mode, the feed and discharge servos operate continuously at manual speed.

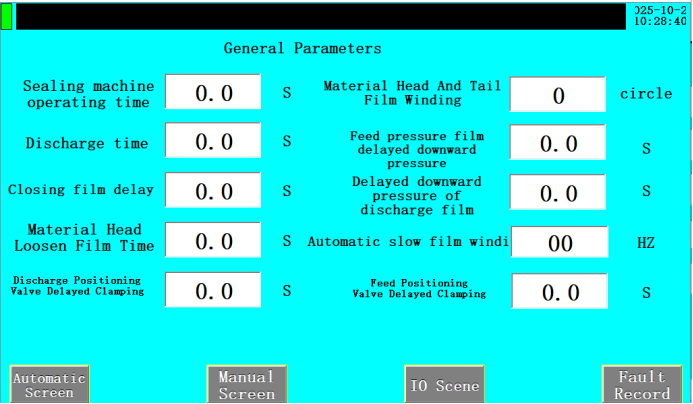

Glue film bundle achine running time: During automatic operation, when the material head or tail is being packaged, wait for the glue film taping to take action.

Discharge time: The time it takes for the discharge servo to run and discharge the material tail after it is wrapped in the sealing machine.

Closing film delay: When the material tail completes the set number of turns on the winding machine, the winding motor will stop with a delay to ensure that the film cylinder is in the mold changing position.

Head loosening time: The time it takes for the cutting blade telescopic cylinder to extend when the feed servo runs again after the head completes the set number of turns at the winding machine position.

Delay clamping of discharge positioning valve: After the material head has wrapped around the film, delay the time to start the discharge positioning cylinder.

Delayed clamping of feeding positioning valve: When the material head senses the feeding electric eye, the positioning cylinder delays clamping;

The number of turns the material head and tail wrap around the film: the number of turns the material head and tail stop at the winding machine for winding.

Delayed feeding film pressing: When the feed head senses the feeding electric eye, the feeding film pressing cylinder delays and presses down again.

Delayed downward pressure of discharge film pressing: When the material head is wound multiple times and the servo is restarted, the discharge film pressing cylinder delays downward pressure.

Automatic film wrapping machine slow speed: The speed of the film winding motor for the last round of automatic film winding.

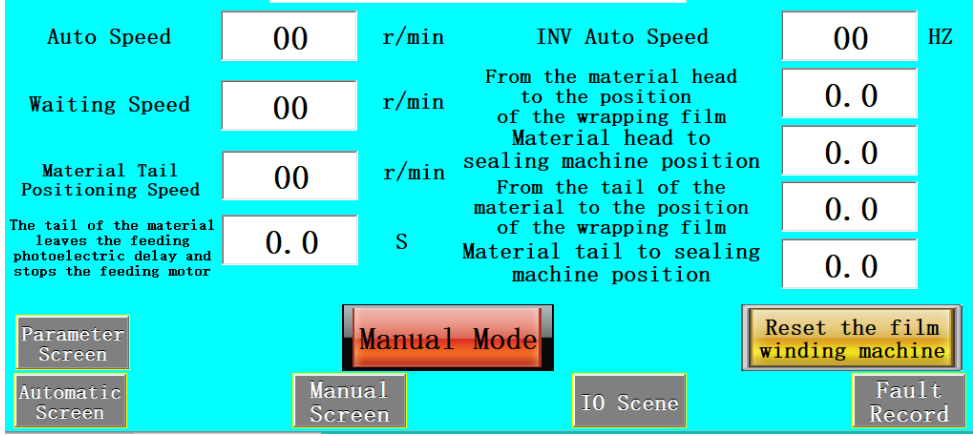

Auto Screen:packing machine auto running testing for aluminum wrapping machine

Manual/Automatic Mode for packing machine: When automatic operation is required, it needs to be switched to "Automatic Mode"

Reset the film bundle machine: In manual mode, reset the position of the film cylinder to the position of the film replacement cylinder.

Automatic speed for packing wrapping machine: The speed at which the feeding and discharging servo automatically operates.

Waiting speed for aluminum wrapping machine: The speed at which the feeding servo waits for the material head to trigger the feeding electric eye.

packing wrapping machine Tail positioning speed: The discharge servo locates the speed of the winding machine after the tail leaves the feeding eye.

When the tail of the material leaves the feeding photoelectric delay stop feeding motor: When the tail of the material leaves the feeding photoelectric delay stop feeding servo, it needs to be increased or decreased according to the automatic speed.

Automatic speed of frequency converter for film bundle machine: the speed of film winding when the winding machine is running automatically.

From the material head to the winding film position: The feeding servo triggers the feeding electric eye based on the material head to move to the relative positioning position of the winding machine.

From the material head to the glue film taping machine position: The feeding/discharging servo triggers the glue film taping machine in place signal based on the distance between the material head and the sealing machine.

From the tail of the material to the position of the winding film: The discharge servo determines the relative positioning distance between the tail of the material and the winding machine from the feeding electric eye.

Tail to glue film taping machine position: The discharge servo determines the relative positioning distance between the tail and the sealing machine based on the signal of the tail leaving the sealing machine.

Auto start operation for aluminum wrapping machine: In automatic mode, after adjusting the parameters, press the auto start button.

Automatic stop operation for packing wrapping machine: When there is no material available and the feeding electric eye does not sense it, the automatic operation can be stopped.

These system parameters are fixed, do not need to change, can design start and end position both have film bundle machine,also can design only one side have film bundle machine. supply customied design, the wrapping speed are also customized.